Overview of 100m3/h 11kw 25m head non-clogging submersible sewage pump:

The main components of 100qw100-25-11 submersible pump are composed of impeller, pump body and base submersible motor. The water pump and the motor are on the same shaft. Since the water pump is located at the bottom of the entire sewage pump, it can maximize the suction of the remaining sewage on the ground. The impeller is designed with double flow channels, which greatly improves the flow capacity of the dirt, and can effectively pass through solid particles whose diameter is 50% of the diameter of the pump. The product implements the standard of Q/TBJW2-2003 “submersible electric pump for sewage and sewage”. “Sewage and sewage submersible pump” standard.

100m3/h 11kw 25m head (100qw100-25-11) submersible pump application scope:

100qw100-25-11 submersible pump is suitable for conveyor belts in chemical, petroleum, pharmaceutical, mining, paper industry, cement plant, steel mill, power plant, coal processing industry, and urban sewage treatment plant drainage system, municipal engineering, construction sites and other industries It can also be used to pump clean water and corrosive media.

100m3/h 11kw 25m head (100qw100-25-11) non-clogging submersible sewage pump model description:

Format: 100WQ 100-25-11

Note: 100——–discharge diameter 100mm

WQ——-W stands for “dirty”, Q stands for “submersible pump”

100——-flow is 100m3/h

25———Head 25m (the first “25”)

11——— Equipped with motor power 11KW

100m3/h 11kw 25m head (100qw100-25-11) non-clogging sewage pump using conditions:

1. The temperature of the medium should not exceed 60℃, and the weight of the medium should be 1~1.3kg/dm3.

2. For pumps without an internal gravity circulating cooling system, the exposed liquid level of the motor part should not exceed ½.

3. The use range of cast iron material is PH5~9.

4. 1Cr18Ni9Ti stainless steel can use various corrosive media.

100m3/h 11kw 25m head (100qw100-25-11) non-clogging submersible sewage pump Main uses:

WQ non-clogging submersible pumps are used in the discharge of seriously polluted wastewater in factories and businesses, sewage discharge stations in residential areas, urban sewage treatment plant drainage systems, civil air defense system drainage stations, water supply devices in water plants, sewage discharge in hospitals and hotels, and municipal engineering buildings. In construction sites, exploration, mine supporting machines, rural biogas digesters, farmland irrigation and other industries, it can also be used for clean water and corrosive media for conveying granular sewage and dirt.

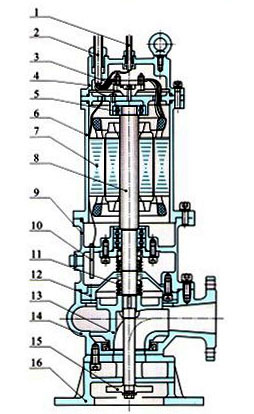

100m3/h 11kw 25m head (100qw100-25-11) sewage submersible pump structure diagram:

1. Signal line; 2. Motor wiring; 3. Junction box; 4. Motor cover;

5. Bearing; 6. Motor shell; 7. Stator; 8. Rotor (shaft);

9. Oil chamber; 10. Oil-water probe; 11. Mechanical seal; 12. Back cover;

13. Impeller; 14. Pump body; 15. Stirring wheel; 6. Chassis.

Post time: 2022-01-08