Pumps below 7.5KW can be directly installed on the foundation with shock isolation pads.

When 7.5KW or more, it can be directly installed with the casting foundation, or we can use our company’s IS connecting plate to cooperate with the shock isolator installation. The installation method of the shock isolator is the same as the size of the shock isolator matched with the ISG pump, and the same specification water pump in the ISG series. The size of the shock isolator is the same.

Installation Notes

1. Before installation, check whether the fasteners of the unit are loose, and whether the flow passage of the pump body is blocked by foreign matter, so as to avoid damaging the impeller and the pump body when the pump is running.

2. The weight of the pipeline should not be added to the pump during installation to avoid deformation of the pump.

3. The anchor bolts must be tightened during installation to avoid the impact of vibration on pump performance during starting.

4. For the convenience of maintenance and safe use, install a regulating valve on the inlet and outlet pipes of the pump and a pressure gauge near the outlet of the pump to ensure operation within the rated head and flow range to ensure the normal operation and growth of the pump. The service life of the pump.

5. Turn the pump shaft after installation, there should be no friction or jamming of the impeller, otherwise the pump should be disassembled to check the cause.

6. The pump is divided into two types: rigid connection installation and flexible connection installation (see connection mode).

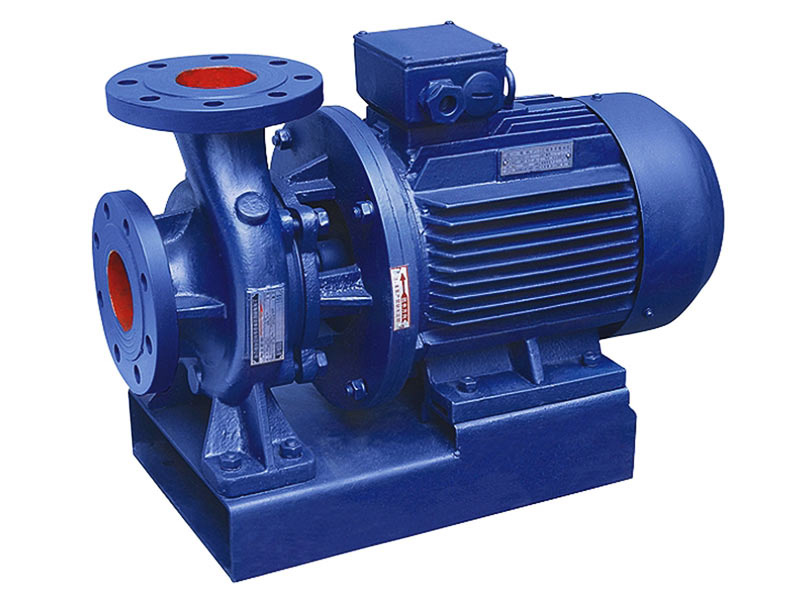

2. ISW horizontal centrifugal pump fault solution (working conditions)

1. The suction pressure is ≤1.0MPa, or the maximum working pressure of the pump system is ≤1.6MPa, that is, pump suction inlet pressure + pump head ≤1.6MPa, and the pump static pressure test pressure is 2.5MPa. Please indicate the system working pressure when ordering. When the working pressure of the pump system is greater than 1.6MPa, it should be stated separately when ordering. In order to use cast steel material for the flow part and connection part of the pump during manufacture.

2. Ambient temperature <40℃, relative humidity <95%.

3. The volume content of solid particles in the conveyed medium does not exceed 0.1% of the unit volume, and the particle size is less than 0.2mm.

Note: If the medium used is with fine particles, please specify when ordering so that the manufacturer can use wear-resistant mechanical seals.

Post time: 2021-11-30